Donghua has established a homogenization laboratory to process various kinds of material samples quickly and efficiently, which can help our customers to get an optimum product quality. Welcome you to our company for sample homogenization experiments and development.

1 Homogenizing effect analysis

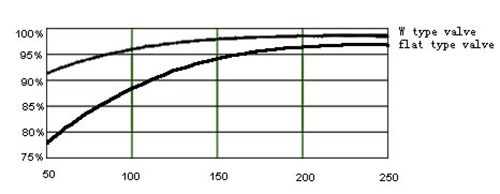

For general materials, the higher the pressure, the finer the grain. Machine below 30MPA is mainly applied in liquid-liquid emulsion. Grade I uses flat valve, and grade II uses W valve. W valve achieves better homogenizing effect and can realize low-cost repeat homogenization.

Homogenizing effect

The comparison between the flat type valve and W type valve (taking milk as an example)

It is applicable to liquid-solid dispersion liquid when homogenizing pressure reaches 30MPA. Diameter of most grains can be less than 2μm when the pressure reaches 60 MPA. The effect will be more obvious if over 80MPA, making grain diameter less than 1μm. When exceeding 100MPA, the grain size can be 0.1-0.5μm.

The homogenizing pressure of different materials

| Fresh milk | below 20Mpa |

| Flavored milk | below 40Mpa |

| Fruit beverage | below 30Mpa |

| Plant protein beverage | below 45Mpa |

| Organic pigment | below 90Mpa |

| Dye | below 90Mpa |

| Bacillus coil | below 60Mpa |

| Saccharomycete | below 90Mpa |

| Fat emulsion | below 100Mpa |

| Grain diameter below 1μm can be got with over 100 MPA pressure | |

| As for the general material, the higher pressure, the finer and more homogeneous the grain will be. Homogenize more times if one time is not enough | |

2 Analysis and discussion of the material layer

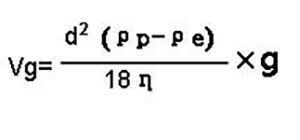

After passing the homogenizer, the material will be layered. Here we will analyze the cause of layering. Putting the material into the liquid, the different density of the material and liquid determine material to be floating or sinking. If the material density is higher than the liquid density, the material will be sinking, vise versa. Under the force of the gravity, the solid grain and liquid droplet will finally reach a steady speed, called SV (sedimentation velocity). SV depends on the following physical quantity:

- Diameter of grain d

- Density of grain ρp

- Density of liquid ρp

- Viscosity of liquid η

- Gravity accelerated speed g(9.8m/s)

- When all these values are given, then SV can be got by the following formula (Stoke's Law)

SV goes up with the increase of d2 (d refers to grain diameter), showing that SV of 5 μm grain is 25 times faster than that of the 1μm grain.

SV rises in lines with the increase of the material density difference

SV increases when the viscosity of material and liquid decreases

18 is a constant

Gravity accelerated speed g is 9.8. Based on the above analysis: high pressure homogenizer can break grains into below 2μm or even finer below 1μm, the diameter of grain is proportional to the square of SV, so grain diameter is the critical factor to determine SV.

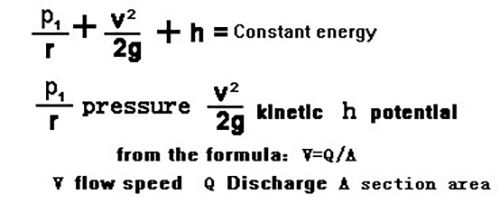

3 Homogenizing theory and void effect

Bernoulli's law (energy conservation law when ideal liquid steadily flowing) the ideal liquid flowing along the sealed tube has three kinds of energy: pressure energy, kinetic energy and potential energy, all of them can be transferred into each other, with the total energy of liquid in any place of the tube constant.

Bernoulli's formula based on above principle

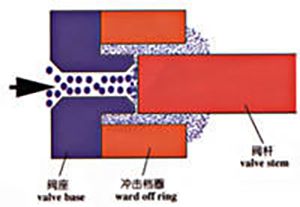

Void effect: the liquid starts boiling and forming into bubbles when the pressure is lower than the saturation steam pressure (meanwhile the air dissolved in the liquid free out turning into bubbles). These bubbles mixed with the liquid cause void, making the liquid discontinuously flow, called void effect.

The material with high pressure and low speed enters into the homogenizing valve, flowing to the low pressure area through the fine span between the column valve and valve seat. Based on Bernoulli's law: pressure energy transfers into kinetic energy, tremendous kinetic energy improves the flow speed to 300-500m/s, while pressure drastically declines below the saturation steam pressure, bubbles formed in the material, this is the void effect. The material loses pressure, expands and explodes. The material grains become super fine because the grain creates strong shear force as passing through the fine span of valve under the huge kinetic effect and crushes into retainer ring at a speed of 300-500m/s (reach 500-1000m/s when100MP) and other comprehensive reasons.

4 Remote control and other applications of homogenizer

With the increasing demand of automatic production, today homogenizers can be independently connected in series with production line, being operated and observed in the control room (machine below 600MP)

In addition to homogenization, homogenizer can also be used in other applications.

The machine can be used as the high pressure plunger pump by changing the homogenizing valve into super-pressure protective safe valve, applying in geological drilling, water injection of deeper earth, high-pressure delivery of chemical fertilizer and chemical liquid etc. It also can be used for a high-pressure spraying. One head of the machine has a high-pressure exit, which once connected with the high-pressure sprayer and can perform spraying immediately. When using valve as overload safety valve, it can be widely applied in fields such as the milk powder and bean powder. Donghua high pressure homogenizer is a versatile machine used for homogenizing and spraying purposes. You can use it to homogenize first and spray afterwards. (Grade I valve as homogenizing pressure and grade II spraying pressure).